Example: Cooling transformers with heat recovery

Reliability is our top priority: failures of grid transformers cause problems with grid control and often lead to power outages and high costs. The reliability of a mains transformer is therefore of great importance. Reliable and fail-safe cooling helps to ensure the operation of a transformer over a long period of time.

A modern cooling system is redundant, efficient and effective. It reliably regulates the oil temperature of the transformer. It provides the operator with online information about the status of the transformer and it recognizes problems independently and warns the operator in good time.

Application example

What is a standard task in open fields is becoming increasingly difficult in densely built-up areas. Transformer stations not only have to be reliable, they also have to blend into the urban environment invisibly and, above all, quietly. An energy-efficient and low-loss cooling system enables an inner-city transformer station to meet the demands of our society. Efficiency is achieved primarily through heat recovery. The transformer waste heat is used to supply the neighbouring buildings.

The challenges

- In the centre of the city

- Safety and reliability

- Noise emission <30dB

- Utilization of waste heat

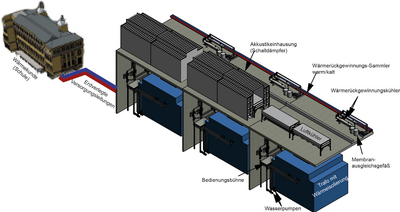

Solution

- Heat transfer from the transformer oil to the coolant with double-tube oil/water cooler incl. leakage monitoring

- Heat transfer from the intermediate circuit to the heat customer (school) with water/water cooler

- Two fully redundant cooling circuits per transformer

- Primary cooling (without heat recovery) by air/water cooler with fans

- Compliance with noise limits (<30dB) thanks to acoustic enclosure