Support optimization is carried out under four main aspects:

- Decreasing the load on the pipeline

- Reduction of the support load

- Feasibility of the new support concept

- Ability to carry the loads through the building connection or the building

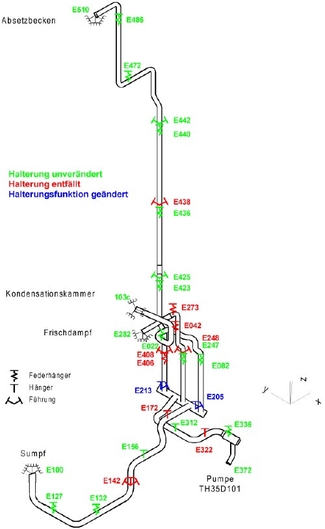

Optimized support concept using the example of the TH30 suction side

Using the example of a residual heat removal line (TH30 suction side) in a boiling water reactor system, it is demonstrated how an optimal support concept can be developed using a structural dynamics analysis program. The existing TH system is designed for traditional static and dynamic load cases such as dead weight, pressure, thermal expansion constraints, and seismic events. The support concept was developed step-by-step initially for static and subsequently for dynamic load cases. Consequently, alongside rigid supports and fixed points, a large number of spring hangers are installed in this system. These require recurring maintenance and inspection activities, which entail high costs for the nuclear power plant operator.

The optimization of the support concept occurs through the integration of static and dynamic load cases. This means that static and dynamic load cases are iteratively calculated together instead of a step-by-step approach. To maximize the multifunctionality of rigid supports, each support must be placed correctly within the piping system. This placement optimally absorbs the weight load, prevents pipe vibration during dynamic excitation, and avoids constraining the pipe during thermal expansion. Additionally, it is crucial to ensure an even distribution of supports throughout the entire system to uniformly utilize the permissible loads of all components (pipes and supports). This approach limits the number of required supports.

Results of the optimisation

As a result of the optimization, the number of supports is reduced from 27 in the current state to 18. The remaining 18 supports consist of 11 spring hangers and 7 rigid supports. Two of the 7 rigid supports will be converted from sliding supports to sliding guides, and repairs will be made to the building connection on two other rigid supports.

The optimization of the support concept for the TH30 suction side has resulted not only in a reduction in the number of supports but also a reduction in the maximum stress utilization in the pipe in the operating and fault load cases. The point load increase on three supports is intended by the concept. From an integral perspective, the optimized support concept leads to a reduction in the support loads, whereby the loads on the component connections remain virtually unchanged.